Advantage Industrial Automation is the premier provider of robotic solutions for all of your applications. With our comprehensive list of partners, we can provide you with the highest quality robotic products and services that are designed to meet your specific needs.

Robots can be used to automate tasks in a variety of industries, such as machine & metal fabrication, food & beverage, consumer packaging, healthcare, electronics, aerospace, and automotive. Our robotic solutions can provide a cost-effective and efficient way to increase productivity, reduce waste, and improve safety.

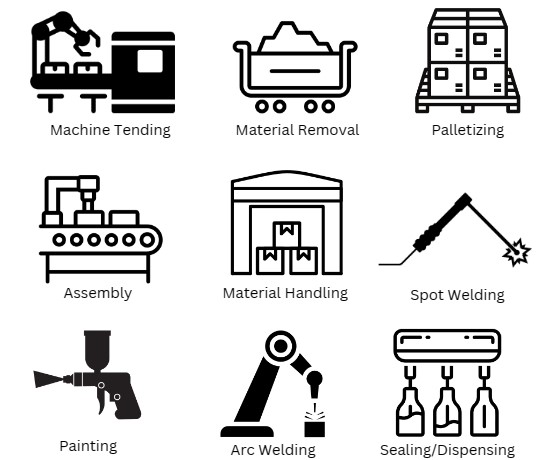

We can provide robot solutions that can be programmed for a variety of tasks such as machine tending, material removal, palletizing, assembly, material handling, spot welding, painting, arc welding, and sealing/dispensing. They can also be used to monitor processes, detect defects, and perform inspections. These robotic solutions can provide your business with the technology needed to stay competitive in today’s markets.

With Advantage Industrial Automation, you can be sure that you’re getting the best robotic solutions for you and your business as we offer a wide range of products and services that are tailored to meet your individual requirements, and our support team is there to help every step of the way. We know how difficult it is to find trained, skilled labor in today’s job market. We can determine how our robotics can provide a safer and cost-effective alternative. These solutions will address all of your current and future application productivity needs.

Contact us HERE for an audit of your application and customized ROI plan!

In 1969, Kawasaki Heavy Industries manufactured the first industrial robot in Japan. Since then, they have stood as a leading robot manufacturer, with their product used around the world. As a pioneer in industrial robot manufacturing, they have developed and supplied high-quality, high-performance robots for a variety of applications such as welding, assembly, material handling, painting, and palletizing. Their robots work in diverse sectors, including the automotive, electrical, and electronics sectors, drawing on technologies and experience accumulated during our decades of experience. They offer solutions that meet customers’ needs for automation, labor-saving efforts, enhanced productivity, quality, and the work environment.

Robotics and Control

PacDrive 3 Robotics, Linear Motion Systems

Lexium MC12 Multicarrier System

Lexium Cobot and Delta Robots

Schneider Electric’s robotic system solutions were developed for a broad range of motion-centric machines in packaging, material handling, material working, electronics and food and beverage applications. Discover their complete portfolio of robots to design a broad spectrum of pick and place or handling solutions. The offer includes PacDrive 3 Robotics, Linear Motion Systems, Lexium MC12 Multicarrier System (see below), Lexium cobot, and Delta robots.

Collaborative Robots, 3 kg to 20 kg Payload

Clean Room, IP66, Stainless Steel

AMR and Star Mobile System

Shenzhen Han’s Robot Co., Ltd. is a national high-tech enterprise invested in and established by Han’s Laser Technology Industry Group Co., Ltd. (stock name: Han’s Laser, stock code: 002008), and incubated based on more than 100 people from the R&D team of Han’s Motor Robotics Research Institute. The company was established in September 2017 and its production and R&D base are located in Shenzhen City and Foshan City, with subsidiaries in Tianjin, Wuxi and Chengdu City. Han’s Robot is dedicated to the development, promotion and application of intelligent robots in industry, healthcare, logistics, services and so on, becoming the global leader in the era of intelligent robots. The offer includes Collaborative Robots, Autonomous Motorized Robots, and Star Mobile System.

More than 2.7 million * industrial robots are in operation around the world * as indispensable equipment for the production of automobiles, home appliances, PCs, smartphones, and other products in factories and other places that are rarely seen in everyday life. Yaskawa announced the Japan’s first all-electric industrial robot under the brand name MOTOMAN in 1977, and since then we have shipped nearly 500,000 units all over the world.

The OnRobot product range features a wide assortment of tools and software for collaborative applications, including electric, vacuum and magnetic grippers, the award-winning Gecko gripping technology, force/torque sensors, a 2.5D vision system, screwdriver, sander kits and tool changers. OnRobot makes it easy to deploy collaborative automation on tasks such as packaging, quality control, material handling, machine tending, assembly, and surface finishing regardless of skill level or previous robotics experience. Their solutions help small and mid-sized manufacturers optimize their processes and grow their businesses with greater flexibility, higher output and improved quality. Collaborative automation has levelled the playing field for small and mid-sized manufacturers, and as robots become easier to buy and implement, the tooling has become the vital element in adapting for a wide range of applications. Regardless of the robot brand, OnRobot provides compatibility and versatility beyond compare. It’s everything manufacturers need from one supplier, providing even more value from the automation investment.

Robotics Vision – Intelligent Sensors for Robotics

Safety Solutions – Human Robot Collaboration

Consulting and Design Risk Assessments

The robot guidance portfolio from SICK covers the full range from powerful high-resolution 3D systems to easily configurable stand-alone 2D systems, ready to solve a specific automation task. The flexibility and modularity built into our machine vision systems enables a combination of camera technology and localization algorithms to ensure the best solution for your application.

mk designs, engineers and manufactures a wide variety of conveyors including belt conveyors, roller conveyors, timing belt conveyors, chain conveyors and flexible flat top chain conveyors; as well as workpiece pallet-handling conveyor systems, and extruded aluminum framing (including guarding and linear motion systems). The variety and flexibility of our offering is unsurpassed, and our products have proven themselves worldwide in a broad variety of applications and industries.

Simulate any Industrial Robot with RoboDK

Generate Robot Programs for any Robot Controller

Directly Download from Your PC

Founded by Albert Nubiola in January 2015, RoboDK is a spin-off company from the CoRo laboratory at ETS University in Montreal, Canada, one of the most prestigious robotics labs in Canada. Simulate any industrial robot with RoboDK. Generate robot programs for any robot controller directly from your PC. RoboDK is a powerful and cost-effective simulator for industrial robots and robot programming.

View our robotic solutions line sheet HERE.